Caterpillar C11 C13 C15 C16 C18 ACERT Truck Engine Service Shop Repair Manual. Is for the caterpillar on-highway engines c-11, c-13, c-15, c-16, and c-18 models that are also known as the. This is an electronic pdf manual on a compact disc, not a hard copy manual. Just like any other cat except you need to remove the jake / vva housings to set valves and injectors. Set valves and injectors on TC compression, rotate 360 to TC exhaust, set valves and injectors. Install jakes and VVA housings. Set 3-5-6 VVA and 2-4-6 exhausts. Rotate 360 again then do 1-2-4 VVA and 1-3-5 exhaust. Use new VVA housing o-rings.

$119.99

Covers: Caterpillar C11 and C13 Truck Diesel Engines with serial number prefixes

- KCA

- KCB

- JAM

Pages: 4,098

Format: PDF

File size: 67mb

Compatibility: Windows/Mac/Tablet

Notes: Bookmarked, searchable, printable, instant download

Cat C13 Valve Adjustment Procedure

This download includes complete service, repair, troubleshooting and specification manuals for Cat C11 and C13 diesel engines with serial number prefixes KCA, KCB and JAM. In this manual set you will find over 4,000 pages of detailed specifications, illustrations, operational information and service procedures to aid with any maintenance, repair or diagnostics the engine may need, including complete disassembly/assembly. The included high resolution manuals can be viewed on your computer, tablet or smartphone, or you can print off pages for the shop without restriction.

Content dated 07/2005.

Manuals included:

- C11, C13 Specifications Manual

- Operation and Maintenance Manual

- Systems Operation Manual

- Testing and Adjusting Manual

- Troubleshooting Manual (with DTCs)

- Disassembly and Assembly Shop Manual

- Electrical Wiring Diagram/Schematic

- Special Instructions

- On-Highway Engines Electronic PTO Installation and Application Guide

- And more…

Topics:

C13 Valve Adjustment

Specifications Manual

- Engine Design

- Fuel Transfer Pump

- Electronic Unit Injector

- Electronic Unit Injector Mechanism

- Electronic Unit Injector Rocker Arm

- Electronic Unit Injector Wiring

- Lifter Group

- Rocker Shaft

- Valve Mechanism

- Cylinder Head Valves

- Cylinder Head

- CAT Compression Brake

- Turbocharger

- Air Lines

- Exhaust Manifold

- Camshaft

- Engine Oil Filter Base

- Engine Oil Cooler

- Engine Oil Pump

- Engine Oil Pan

- Precooler

- Water Temperature Regulator Housing

- Water Temperature Regulator

- Water Pump

- Cylinder Block

- Cylinder Liner

- Cylinder Liner Projection

- Crankshaft

- Crankshaft Seals

- Connecting Rod Bearing Journal

- Main Bearing Journal

- Connecting Rod

- Connecting Rod

- Piston and Rings

- Piston Cooling Jet

- Housing (Front)

- Gear Group (Front)

- Gear Group (Rear)

- Flywheel Housing

- Flywheel Housing

- Engine to Transmission Adapter

- Belt Tensioner

- Electric Starting Motor

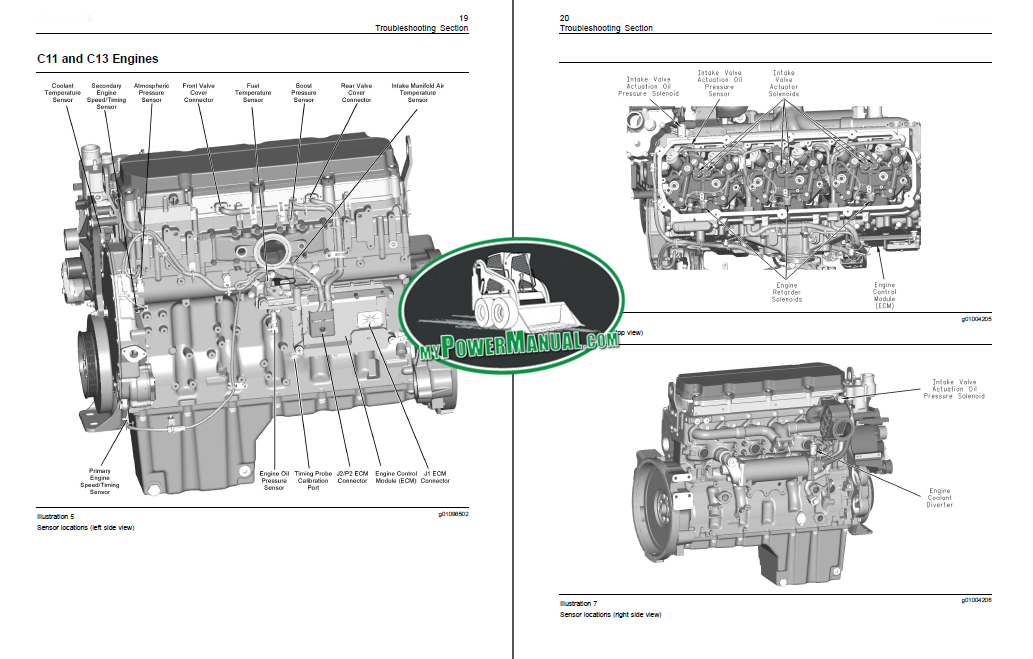

- Coolant Temperature Sensor

- Fuel Temperature Sensor

- Engine Oil Pressure Sensor

- Boost Pressure Sensor

- Atmospheric Pressure Sensor

- Inlet Manifold Temperature Sensor

- Speed/Timing Sensor

Systems Operation Manual

- Engine Design

- Engine Design

- General Information

- Electronic Control System Components

- Fuel System

- Air Inlet and Exhaust System

- Lubrication System

- Cooling System

- Basic Engine

- CAT Compression Brake

- Electrical System

Testing and Adjusting Manual

- Fuel System

- Fuel System – Inspect

- Air in Fuel – Test

- Electronic Unit Injector – Adjust

- Electronic Unit Injector – Test

- Finding Top Center Position for No. 1 Piston

- Fuel Quality – Test

- Fuel System – Prime

- Fuel System Pressure – Test

- Gear Group (Front) – Time

- Air Inlet and Exhaust System

- Air Inlet and Exhaust System – Inspect

- Turbocharger – Inspect

- Inlet Manifold Pressure – Test

- Aftercooler – Test

- Engine Crankcase Pressure (Blowby) – Test

- Compression – Test

- Engine Valve Lash – Inspect/Adjust

- Variable Valve Actuators – Inspect/Adjust

- Lubrication System

- Engine Oil Pressure – Test

- Engine Oil Pump – Inspect

- Excessive Bearing Wear – Inspect

- Excessive Engine Oil Consumption – Inspect

- Increased Engine Oil Temperature – Inspect

- Cooling System

- Cooling System – Check (Overheating)

- Cooling System – Inspect

- Cooling System – Test

- Water Temperature Regulator – Test

- Water Pump – Test

- Basic Engine

- Piston Ring Groove – Inspect

- Connecting Rod Bearings – Inspect

- Main Bearings – Inspect

- Cylinder Block – Inspect

- Cylinder Liner Projection – Inspect

- Flywheel – Inspect

- Flywheel Housing – Inspect

- Vibration Damper – Check

- Compression Brake

- CAT Compression Brake Lash – Adjust

- Electrical System

- Battery – Test

- Charging System – Test

- Electric Starting System – Test

- Pinion Clearance – Adjust

Disassembly and Assembly Manual

- Fuel Filter Base

- Fuel Transfer Pump

- Electronic Unit Injector

- Electronic Unit Injector Sleeve

- Turbocharger

- Exhaust Manifold

- Inlet and Exhaust Valve Springs –

- Inlet and Exhaust Valves

- Inlet and Exhaust Valve Guides

- Inlet and Exhaust Valve Seat Inserts

- Engine Oil Filter Base

- Engine Oil Cooler

- Engine Oil Pump

- Diverter Valve (Oil)

- Diverter Valve (Coolant)

- Water Pump

- Water Temperature Regulator

- Precooler

- Flywheel

- Flywheel Housing

- Front Cover

- Gear Group (Front

- Housing (Front)

- Accessory Drive

- Valve Mechanism Cover Base

- Valve Actuator (Variable)

- Rocker Shaft and Pushrod

- Rocker Shaft

- Rocker Shaft and Pushrod

- Cylinder Head

- Lifter Group

- Camshaft

- Camshaft Gear

- Camshaft Bearings

- Engine Oil Pan

- Cylinder Liner

- Piston Cooling Jets

- Pistons and Connecting Rod

- Connecting Rod Bearings

- Crankshaft Main Bearings

- Crankshaft

- Crankshaft Gear

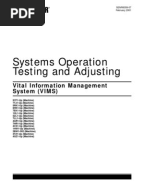

- Engine Sensors

- Fan Drive Mounting Group

- Engine Control Module

- Air Compressor

Troubleshooting Manual

- System Overview

- Electronic Service Tools

- Replacing the ECM

- Sensors and Electrical Connectors

- Programming Parameters

- Dyno Mode

- Test ECM Mode

- Customer Passwords

- ECM Date/Time Stamped Information

- ECM Snapshot

- Factory Passwords

- Factory Passwords Worksheet

- Flash Programming

- Service Information Report

- Customer Specified Parameters

- Customer Specified Parameters Table

- Customer Specified Parameters Worksheet

- Cruise Control Parameters

- Data Link Parameters

- Dedicated PTO Parameters

- Driver Reward

- ECM Identification Parameters

- Engine/Gear Parameters

- Engine Monitoring Parameters

- Idle Parameters

- Input Selections

- Maintenance Parameters

- Output Selections

- Security Access Parameters

- Selected Engine Rating

- Smart Idle Parameters

- Timer Parameters

- Trip Parameters

- Vehicle Activity Report Parameters

- Vehicle Speed Parameters

- System Configuration Parameters

- System Configuration Parameters

- Troubleshooting without a Diagnostic Code

- Can Not Reach Top Engine RPM

- Can Not Reach Vehicle Speed Limit

- Check Engine Lamp or Warning Lamp Is

- Malfunctioning

- Cooling Fan Is Always ON

- Cruise Control, Idle, or PTO Can Not Be Set

- Driver Questionnaire

- Driver Questionnaire Response

- ECM Will Not Accept Factory Passwords

- Electronic Service Tool Will Not Communicate with ECM

- Engine Cranks but Will Not Start

- Engine Misfires, Runs Rough or Is Unstable

- Engine Retarder (Compression Brake) Will Not Turn ON

- Engine Vibration

- Engine Will Not Crank

- Excessive Black Smoke

- Excessive Fuel Consumption

- Excessive White Smoke

- Intermittent Cruise Control, Idle, or PTO Kickout

- Intermittent Low Power or Power Cutout

- Low Power/Poor or No Response to Throttle

- Poor Acceleration or Response

- Troubleshooting with a Diagnostic Code

- No Diagnostic Code Detected

- Injector current low

- Injector current high

- Primary to Secondary Engine Speed Signal Calibration

- Engine Speed Signal Calibration Not Performed

- PTO Throttle signal invalid

- PTO Throttle out of calibration

- 8 Volt Supply voltage high

- 8 Volt Supply voltage low

- Key Switch Fault

- Air Inlet Shutoff Shutdown

- Auxiliary Output #06 current low

- Auxiliary Output #06 current high

- Auxiliary Output #07 current low

- Auxiliary Output #07 current high

- Secondary Engine Speed loss of signal

- Idle Shutdown Override

- Idle Shutdown

- PTO Shutdown

- Vehicle Overspeed Warning

- Vehicle Speed loss of signal

- Vehicle Speed signal invalid

- Vehicle Speed signal out of range

- Vehicle Speed signal rate of change

- Quick Stop Occurrence

- And Much More…

- 5 Volt Engine Pressure Sensor Supply Circuit – Test

- Accelerator Pedal (Throttle) Position Sensor Circuit – Test 2

- Air Inlet Shutoff Circuit – Test

- ATA (SAE J1587 / J1708) Data Link Circuit – Test

- Auxiliary Brake Circuit – Test

- Check Engine Lamp Circuit – Test

- Clutch Pedal Position Switch Circuit – Test

- Coolant Level Sensor Circuit – Test

- Cooling Fan Circuit and A/C High Pressure Switch Circuit – Test

- Cruise Control Switch Circuit – Test

- Diagnostic Enable Switch Circuit – Test

- Eaton Top 2 Transmission Circuit – Test

- ECM Memory – Test

- Electrical Connectors – Inspect

- Engine Coolant Diverter Circuit – Test

- Engine Pressure Sensor Open or Short Circuit – Test

- Engine Running Output Circuit – Test

- Engine Shutdown Output Circuit – Test

- Engine Speed/Timing Sensor Circuit – Test

- Engine Temperature Sensor Open or Short Circuit – Test

- Fan Override Switch Circuit – Test

- Idle Shutdown Timer – Test

- Ignition Keyswitch Circuit and Battery Supply Circuit – Test

- Ignore Brake/Clutch Switch Circuit – Test

- Injector Solenoid Circuit – Test

- Intake Valve Actuation System Oil Pressure Circuit – Test

- Intake Valve Actuator Circuit – Test

- Intake Valve Actuator Response – Test

- Multi-Torque – Test

- Neutral Switch Circuit – Test

- Powertrain Data Link Circuit – Test

- PTO Engine RPM Set Speed (Input A and Input B)

- Circuit – Test

- PTO Shutdown Timer – Test

- PTO Switch Circuit – Test

- PTO Switch ON Lamp Circuit – Test

- Remote PTO Accelerator Position Sensor Circuit – Test

- Retarder (Compression Brake) Solenoid Circuit – Test

- Service Brake Pedal Position (Switch 1) Circuit – Test

- Service Brake Pedal Position (Switch 2) Circuit – Test

- Starting Aid Output Circuit – Test

- Starting Aid Switch Circuit – Test

- Tachometer Circuit – Test

- Torque Limit Switch Circuit – Test

- Two Speed Axle Switch Circuit – Test

- Vehicle Speed and Speedometer Circuit – Test

- Warning Lamp Circuit – Test

- Calibration Procedures

- Engine Speed/Timing Sensor – Calibrate

- Injector Code – Calibrate

- Vehicle Speed Circuit – Calibrate

Wiring Schematic (Foldout size – includes engine, harness and connector views)

And much more…

Related products

- A complete, step-by-step explanation of how the the various systems work, along with pictures/diagrams

- Provides the technician the information needed to perform each test properly. Shortens diagnostic time & enhances work quality

- Provides all the correct procedures.

Cat C13 Valve Adjustment Manual Instructions

Aids the technician with:

- Systems operations

- Performing testing

- Adjusting procedures.

Coverage:

System Operation Section

- Engine Design

- General Info

- Electronic Control System Components

- Fuel System

- Inlet & Exhaust System

- Lubrication System

- Cooling System

- Electrical System

Cat C13 Valve Adjustment

Testing & Adjusting Section

- Electronic Control System

- Fuel System

- Inlet & Exhaust System

- Lubrication System

- Cooling System

- Belt Tension Info

- Electrical System

- Block

Cat C13 Valve Adjustment Manual Download

Caterpillar C11 & C13 Systems Operations, Testing & Adjusting Manual

Manuals normally ship out within 24 hours.